Products

2021 High quality Mg Powder - Atomized Spherical Magnesium Alloy Powder – YANXA

2021 High quality Mg Powder - Atomized Spherical Magnesium Alloy Powder – YANXA Detail:

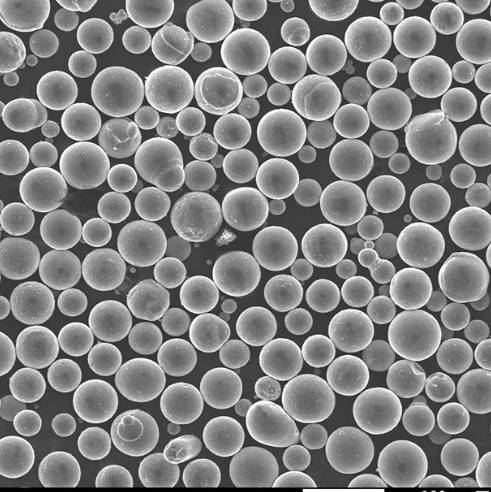

Atomized spherical magnesium alloy powder

Developed for the powder consumables of 3D laser printing. The spherical magnesium alloy powder is the low-oxygen, low-nitrogen and spherical powder produced under the protection of inert gas.

1. Chemical component

Magnesium alloy powder AZ91D

Density of magnesium alloy AZ91D is less than 2g/cm3, it is the lightest metal structure material currently, its specific strength is higher than aluminium alloy and steel, easy to process and low processing cost, corrosion resistance is greatly stronger than the low carbon steel, and it has exceeded die-casting aluminum A380, its vibration-damping behavior and magnetic shielding property are more superior than aluminum alloy. Chemical components are as follows:

| Component | Mg | Al | Cu | Fe | Mn | Ni | Si | Zn | Be |

| Ratio% | 90.43 | 8.90 | 0.0006 | 0. 0112 | 0.19 | 0.0030 | 0.0030 | 0.4278 | 0.00098 |

Magnesium alloy powder ZK61

Magnesium alloy ZK61 is namely the magnesium-zinc-zirconium alloy, and its chemical components are as follows:

| Magnesium alloy ZK61 is namely the magnesium-zinc-zirconium alloy, and its chemical components are as follows: | Mn | Zr | Zn | Fe | Mn | Ni | Si | Cu | Al |

| Ratio% | 94.46 | 0.33 | 5.1953 | 0.0035 | 0.0055 | 0.0030 | 0.0007 | 0.0010 | 0.0006 |

2. Specification

The granularity of the atomized spherical magnesium alloy powder is within 20-1000 mesh, and it can be produced according to customer’s demands.

3. Performance of magnesium alloy powder

(1) Inert gas shielding process is taken, O, N and other impurity content is low, and impurity is high;

(2) Rapid cooling process is taken, magnesium alloy powder has fine grain;

(3) Atomization technique is taken, magnesium alloy powder is spherical and liquidity is good.

4. Application area

The atomized spherical magnesium alloy powder produced by our company can be widely used in 3D laser printing additive manufacturing consumables, novel electronic packaging material and other field, and also can be used in aerospace, automobile parts and 3C product.

Product detail pictures:

Related Product Guide:

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for 2021 High quality Mg Powder - Atomized Spherical Magnesium Alloy Powder – YANXA , The product will supply to all over the world, such as: Angola, France, India, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.