Products

PriceList for 3d Printing Metal Powder - Atomized Spherical Aluminum Magnesium Alloy Powder – YANXA

PriceList for 3d Printing Metal Powder - Atomized Spherical Aluminum Magnesium Alloy Powder – YANXA Detail:

Atomized spherical aluminum magnesium powder

The atomized spherical aluminum magnesium alloy powder produced by atomization method also has high purity, high apparent density, high liquidity, small specific area and other significant feature.

Product Specification

Matching range is mainly Al-Mg 5:5, Al-Mg 8:2, Al-Mg 6:4 and Al-Mg 4:6.

The distribution of particle size is within 30-1000 meshes (15um—500um), and tailor-made granulation is available for specific purpose.

Notes

1) all the technical data indicated above are for your reference.

2) alternative specification is welcome for further discussion.

Product Characteristic

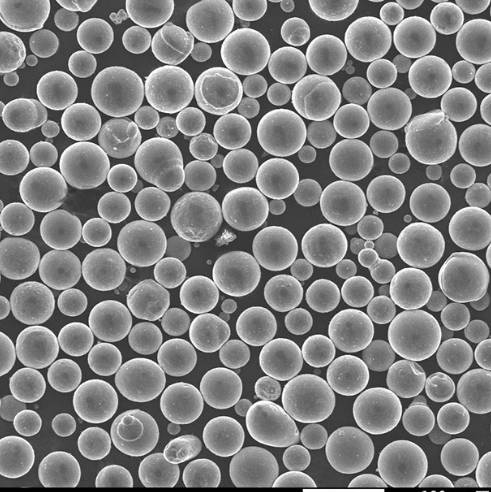

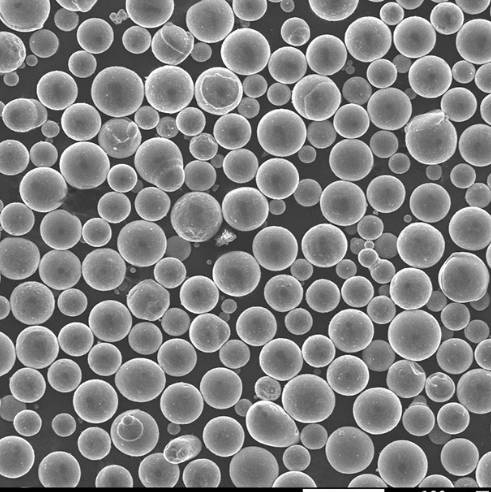

1.Regular particle shape: production technique of atomization method taken by us decides that our magnesium powder is solid and spherical, and particle shape is regular.。

2.High spherical rate: atomized aluminum magnesium alloy powder has high spherical rate, the reaction activity of each point on the surface of the particle is similar or same, with stable reaction. At the same time, sphere surface lowers the friction sensitivity of powder, compared with milling magnesium powder, it is safer from the aspects of handling transportation and production blending.

3.Large apparent density: the more the apparent density is, the higher the upper limit of explosive payload is, the more the active ingredient content participating in reaction is, and the wide the adjustable range of the explosive payload is.

4.Good liquidity: even particle shape and high spherical rate decide its good liquidity, the better the liquidity is, the more even the blending property with other medicament is, the more stable the reaction and the better is compatibility is.

5.High active Mg +Al content: the more the active Mg+Al content, the more the active ingredient content participating in reaction is, and the better the controllability of main reaction is, which not only can save cost, but also can reduce side reaction.

6.High active Mg +Al content: the more the active Mg+Al content, the more the active ingredient content participating in reaction is, and the better the controllability of main reaction is, which not only can save cost, but also can reduce side reaction.

Performance comparison between atomization and mechanical aluminum magnesium alloy powder

|

Product Performance |

atomized aluminum magnesium alloy powder |

Mechanical aluminum magnesium alloy powder |

|

|

Particle shape |

Spherical particle |

Irregular shape |

|

|

Spherical rate /% |

≥95 |

- |

|

|

Apparent density /g·cm-3 |

≥1.2 |

0.826 |

|

|

Liquidity/s·(50g)-1 |

53 |

- |

|

|

Al content/% |

50.14 |

50.14 |

|

|

Moisture absorption/% |

0.01 |

0.09 |

|

|

Active Mg +Al content/% |

99.25 |

90.58 |

|

|

Impurity content/ % |

Fe |

0.0482 |

0.2531 |

|

Cl-1 |

0.003 |

0.02 |

|

|

H2O |

0.08 |

0.1 |

|

|

Cu |

0.0024 |

0.3605 |

|

|

Cr |

0.0524 |

0.396 |

|

|

Zn |

0.0152 |

0.3432 |

|

|

Ni |

0.0062 |

0.0199 |

|

|

Ca |

0.1475 |

0.2318 |

|

|

Mn |

0.0159 |

0.0602 |

|

|

Pb |

0.0194 |

0.1838 |

|

Product detail pictures:

Related Product Guide:

We will make just about every exertion for being excellent and perfect, and speed up our actions for standing during the rank of worldwide top-grade and high-tech enterprises for PriceList for 3d Printing Metal Powder - Atomized Spherical Aluminum Magnesium Alloy Powder – YANXA , The product will supply to all over the world, such as: Paris, Jamaica, Irish, Our professional engineering group will always be ready to serve you for consultation and feedback. We're able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to offer you the ideal service and goods. For anyone who is thinking about our company and merchandise, be sure to contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Be sure to feel free to get in touch with us for business and we believe we've been intending to share the top trading practical experience with all our merchants.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.