Products

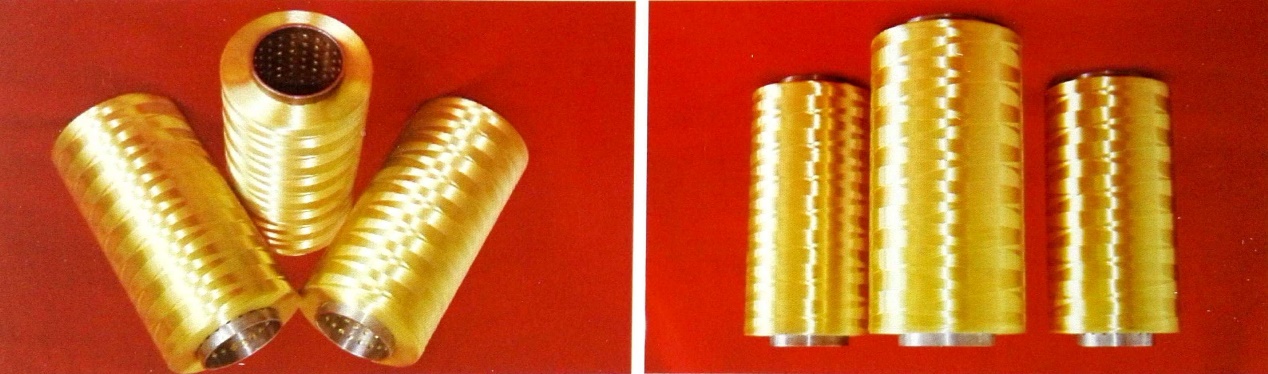

F-12 Aramid fiber

F-12 series products have been widely used in helicopters, fixed-wing aircraft engines, aerospace high-pressure gas cylinders, rocket shells and outer thermal protection layers, airship skin materials, personal protective equipment, high-performance radomes, rubber products, special ropes and webbands, etc.

Aramid fibers feature some general characteristics that distinguish them from other synthetic fibers:

- High strength

- Low density

- High flexibility

- Good resistance to impaction

- Good resistance to cutting

- Anti-fatigue

- Good insulation

- Good resistance to chemical corrosion

- Good resistance to low and high temperature

- Good wave transmission

- Good size stability

Chemical and physical property of F-12 Aramid fiber

|

Density (g/cm3) |

1.43±0.1 |

Limited Oxygen index (LOI) |

35 |

|

Saturated moisture absorption (%) |

≤3.0 |

Heat expansion index (10-6/K |

±1 |

|

Glass transition temperature (℃) |

264 |

Decomposition temperature (℃) |

|

|

High temperature performance |

200℃, strength lowered by 25% for 100 hours |

Low temperature performance |

Strength maintains the same at -194℃ |

|

Dielectric constant |

3.4 (23℃) |

Dielectric loss |

0.00645 (23℃) |

|

Creep property |

60% breaking load, 300 days, creeping increment 0.131% |

||

Mechanical property of F-12 Aramid fiber

|

Model |

23T |

44T |

44THM |

63T |

100T |

130T |

200T |

|

Line density(tex) |

23±2 |

44±3 |

44±3 |

63±4 |

100±5 |

130±5 |

200±5 |

|

Impregnation tensile strength (GPa) |

≥4.3 |

≥4.3 |

≥4.0 |

≥4.2 |

≥4.2 |

≥4.2 |

≥4.2 |

|

Impregnation elastic module (GPa) |

≥120 |

≥120 |

≥145 |

≥120 |

≥120 |

≥120 |

≥120 |

|

Elongation (%) |

≥2.6 |

||||||

F-12 Aramid fiber fabric

Various structure fabrics made of F-12 aramid fiber for different application.

|

Model |

Structure |

Thickness(mm) |

Surface density(g/m2) |

Tensile breaking strength |

|

|

Warp wise |

Across warp |

||||

| 023A060 |

Plain weave |

0.12 |

61±7 |

1400 |

1500 |

| 023A077 |

Plain weave |

0.13 |

≤77 |

1875 |

1875 |

| 023F |

8/3 warp sateen |

0.14 |

88±5 |

2400 |

2300 |

| 044B |

5/2 warp sateen |

0.2 |

120±10 |

2600 |

2900 |

| 100C170 |

Satinet weave |

0.3 |

170±10 |

4500 |

4700 |

| 100A200 |

Plain weave |

0.32 |

200±10 |

4800 |

4800 |